316 Stainless Steel Push in Fittings

316 Stainless Steel Push to Connect Fittings

As a super kind of push in fittings, 316 stainless steel push-in fittings (also called 316 stainless steel push to connect fittings) provide easy tube insertion and removal for rapid assembly. 316 stainless steel push in fittings are suitable for applications in corrosive environments where brass and acetal are typically prohibited. Pneuflex's 316 stainless steel push in fittings are made from forged 316 stainless steel or machined bar stock.

Advantages of Pneuflex's 316 stainless steel push-in fittings:

- Resistant to aggressive environments

- Suitable for food and beverage applications (FDA standards)

- Elbows and Tees are made from forged 316 stainless steel

- Elbows and Tees can be 360° swiveled

- FKM (Viton) o-ring sealing in all 316 stainless steel push in fittings

- Can be used with steam, oil, water and other fluids.

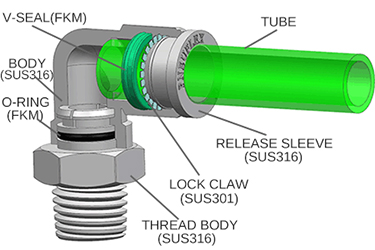

Construction | Specifications

Body Material: 316 Stainless Steel

Thread Material: 316 Stainless Steel

Seal, O-ring: FKM (Viton)

Working Pressure: 0∼2.0MPa | 0∼290psi

Proof Pressure: 3.0Mpa | 435psi

Negative Pressure: -100Kpa | -29.5 In Hg

Working Temperature: -20∼150°C | -4∼302°F

Lock Claw: Stainless Steel(SUS)

Applicable Tube: PU / PA / PE / Teflon (PTFE) Tubing ...

Products of 316 Stainless Steel Push in Fittings

Applications of 316 Stainless Steel Push in Fittings

Pneuflex's 316 stainless steel push in fittings are ideal for the applications where high temperature and corrosions resistance are important. 316 stainless steel push in fittings are widely used in the applications of food process, paper, petrochemical, pharmaceutical, chemical and medical etc.