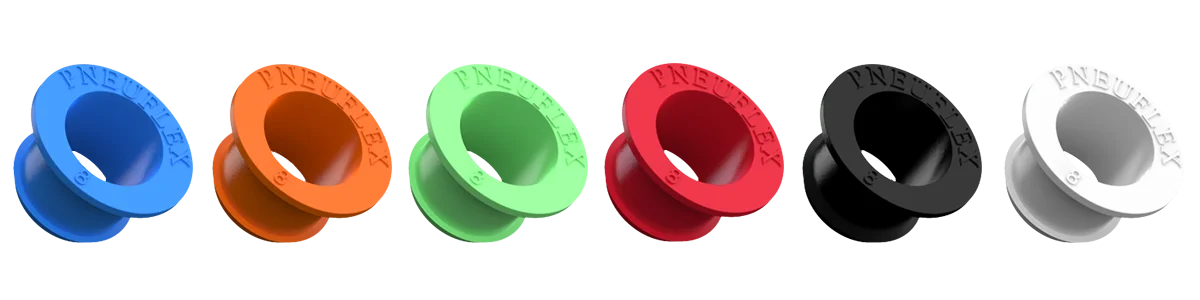

Pneumatic Silencers | Pneumatic Mufflers | Pneumatic Filters

Pneumatic silencers ( or Pneumatic mufflers) are used to suppress the exhaust noise of air release and avoid contamination at the exhaust ports of pneumatic components. Available materials include sintered bronze, plastic and sintered stainless steel. Available thread size ranges from M5, 10-32UNF to 2".

Function of Pneumatic Silencers and Pneumatic Mufflers

- For noise reduction

- As filters to prevent metal chips, abrasive grits, dust and other contaminants from entering open exhaust ports, thus pneumatic devices are protected.

The material of Pneuflex's pneumatic silencers are available in :

- Sintered Bronze

- Porous Plastic

- Sintered Stainless Steel (SS304, SS316, SS316L)

- Stainless Steel Wire Mesh (SS304, SS316, SS316L)

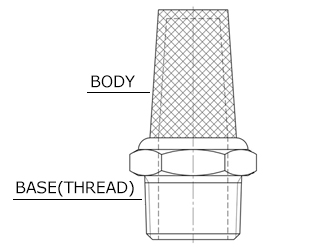

Construction | Specifications

Working Pressure: 0~1.0MPa | 0~150psi

Proof Pressure: 3.0Mpa | 435psi

Negative Pressure: -100Kpa | -29.5 In Hg

Working Temperature: -10~80°C | 14~176°F

Body(noise absorbing material): Sintered Bronze, Sintered Stainless Steel, Polyethylene

Base(thread): Brass, Stainless Steel, Polyethylene

PT, R, BSPT - 55° Taper Pipe Thread

| Thread | R1/16 | R1/8 | R1/4 | R3/8 | R1/2 | R3/4 | R1 | R1-1/4 | R1-1/2 | R2 |

| Code | 1/16 | 01 | 02 | 03 | 04 | 06 | 08 | 10 | 12 | 16 |

BSPP, G - 55° Parallel Pipe Thread

| Thread | G1/16 | G1/8 | G1/4 | G3/8 | G1/2 | G3/4 | G1 | G1-1/4 | G1-1/2 | G2 |

| Code | G1/16 | G01 | G02 | G03 | G04 | G06 | G08 | G10 | G12 | G16 |

NPT - 60° American Standard Taper Pipe Thread

| Thread | 1/16NPT | 1/8NPT | 1/4NPT | 3/8NPT | 1/2NPT | 3/4NPT | 1NPT | 1-1/4NPT | 1-1/2NPT | 2NPT |

| Code | N1/16 | N01 | N02 | N03 | N04 | N06 | N08 | N10 | N12 | N16 |

Metric Thread

| Thread | M3 x 0.5 | M4 x 0.7 | M5 x 0.8 | M6 x 1 | M8 x 1 | M8 x 1.25 | M10 x 1 | M10 x 1.25 | M10 x 1.5 | M12 x 1.25 | M12 x 1.5 | M14 x 1.5 | M16 x 1.5 | M16 x 2 | M20 x 1.5 | M20 x 2 | M22 x 1.5 | M22 x 2 |

| Code | M3 | M4 | M5 | M6 | M8 x 1 | M8 x 1.25 | M10 x 1 | M10 x 1.25 | M10 x 1.5 | M12 x 1.25 | M12 x 1.5 | M14 x 1.5 | M16 x 1.5 | M16 x 2 | M20 x 1.5 | M20 x 2 | M22 x 1.5 | M22 x 2 |

Products of Pneumatic Mufflers | Pneumatic Silencers | Filters

Considerations in Choosing Pneumatic Silencers (Pneumatic Mufflers)

Pneumatic silencers (or usually called pneumatic mufflers in America) are a cost-effective and simple solution to reduce exhaust noise level and filter contaminants. Pneumatic silencers are designed in different noise absorbing material (housing materials) and shapes depending on the applications, mainly sintered bronze, porous plastic and stinered stainless steel. The following should be considered in choosing the correct pneumatic silencers type:

- Noise absorbing material - Sintered bronze is suitable for non-corrosive and neutral environments. Porous plastic is suitable for corrosive environments but max application temperature is lower. Sintered Stainless steel is an excellent choice for applications which require corrosion protection, durability, and/or operating in a sterile environment. But Stainless steel silencers are generally more expensive than sintered bronze or plastic silencers.

- Working temperature - Plastic silencers work at: -10°C~60°C | 14°F~140°F. Sintered bronze silencers work at -10°C~60°C | 14°F~140°F. Sintered stainless steel silencers work at -25°C~150°C | -13°F~302°F, the max working temperature of stinered stainless steel silencers could be litter higher.

- Working Pressure - Working pressure of sintered bronze, plastic and sintered stainless steel silencers could be up to 3Mpa (435psi). But sintered bronze and stainless steel silencers could work at higher pressure.

- Filteration Rating - Sintered bronze and porous plastic: 30-45 micron. Sintered stainless steel: 20-30 micron. Stainless steel wire mesh: 80-300 micron.

- Flow Control and Non-Flow Control - Throttle vavles are built inside silencers, thus the flow rate of air as it exits the silencer could be ajusted easily. Flow control silencers are useful to control the speed of a driving device and work similar to needle valves. Presently, Pneuflex has five types of sintered bronze silencers: BESL Speed Control Silencer, BESLC Speed Control Silencer, BESLD Flow Control Silencer, BESL-S Slot Speed Control Silencer and BESLC-S Slot Speed Control Silencer and one type of sintered stainless steel silencer: SESLC-S Stainless Steel Flow Control Exhaust Silencer.

Applications of Pneumatic Mufflers (Pneumatic Silencers)

Pneumatic silencers can be applied in many applications that operate pneumatic devices and components at a high frequency and produce a large amount of noise are well suited for pneumatic silencers.